Low Stock - Order now before we sell out!

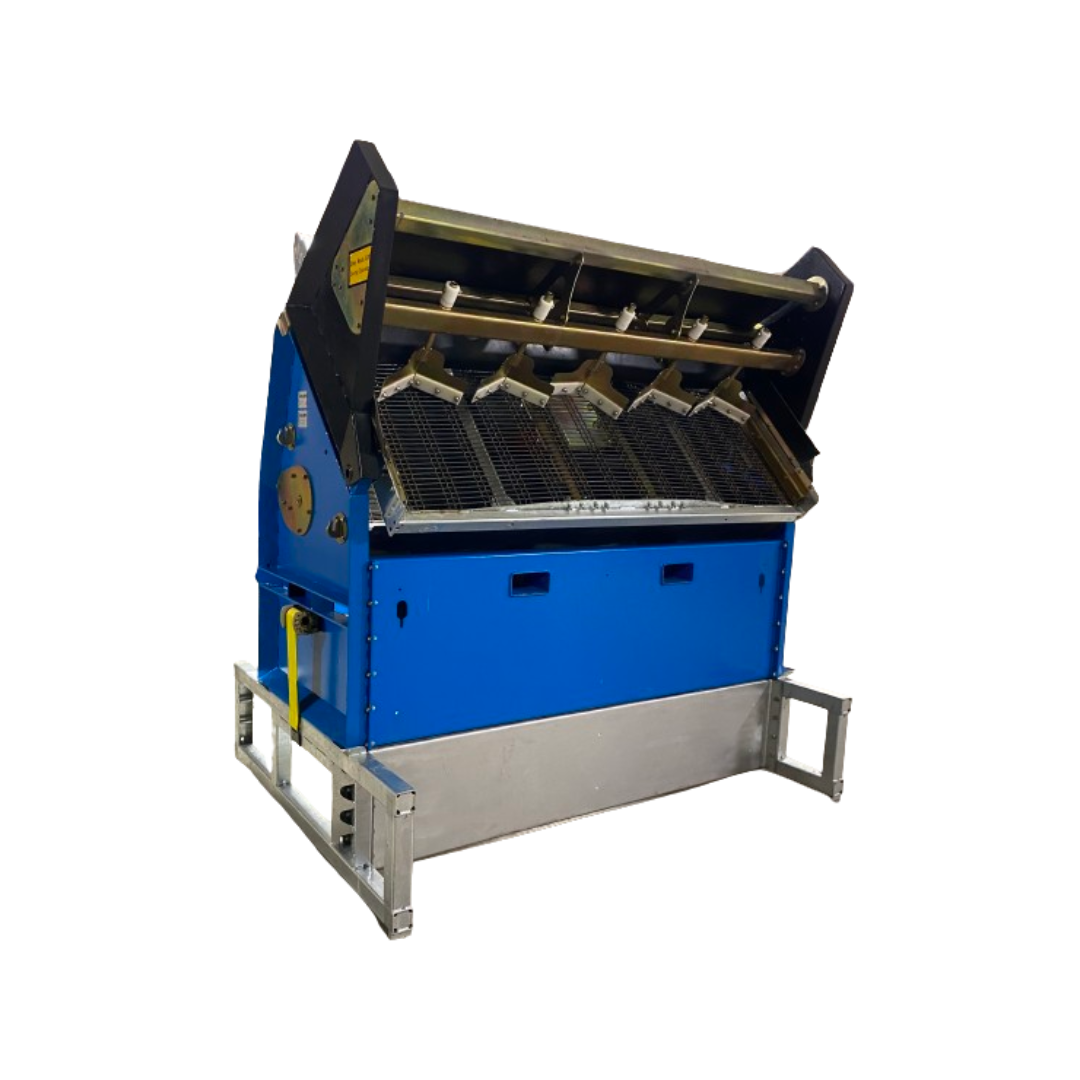

78 ProScreen Topsoil & Rock Screener

Bucket Tractors | Skidsteers | Excavators | Compact Loaders

DeSite 78 ProScreen vibratory screener is our midsize portable vibratory screener, designed to be fed with skidsteers, bucket tractors, midsize excavators and compact loaders. Our rugged SLG 78VF will produce 15 to 30 yards per hour depending upon mesh, material being screened, and the type and size of machine feeding the screener. When you see the 78 ProScreen up close, you are going to find features built into the design that only found on SLG screeners.

Our Tilting Screen Deck, Feed Deflector System, Cantilevered Spring Suspension, and Grab and Go Portability are all features that set our SLG screeners apart from all other screening machines.

Tilting Screen Deck

An operators ability to manipulate the slope of a screen deck while screening makes for better efficiency and bigger production. That is why all SLG screening machines come fitted with the ability to adjust the screen deck to varying positions for varying materials with varying moisture levels. These topsoil screeners perform well in all soil conditions: wet, dry, sandy, rocky and even frozen soil. To move the material slowly across the mesh bring the screen deck to a flatter position. This works best for screening products like sand. To keep material moving like when screening high moisture soils that can plug a low sloped screen deck you have the ability to bring the DeSite SLG screen deck to a steeper position to keep material from plugging the mesh during the screening process. Changing the deck slope is quick and easy.- Loosen the 5 deck mount bolts on each side of the screener.

- Adjust the screen deck to the desired slope.

- Tighten the 5 deck mount bolts on each side and resume screening.

Feed Deflector System

Only on a DeSite screener will you find a Feed Deflection System that funnels material to the top of the screen deck to begin the screening process. Early on in designing the 78 ProScreen, we recognized the need to control and direct the flow of material being screened. Forcing material to the top of the screen deck to begin the process allows for maximum production and maximum efficiency. The feed deflector on the 78 ProScreen allows the operator to feed the screener faster and more aggressively. The feed deflector on the 78 ProScreen mounts into quick disconnect lugs that allow the feeder to tip forward allowing oversize material pass over the screen deck and into the overs pile. When screening very trashy material will lots of oversize stumps, big roots and construction debris, the feeder can be completely removed turning the screener into a standard deck screen like all others.

Cantilevered Suspension

Another feature you will only find on a DeSite SLG screener is our cantilevered suspension system that allows the screen deck to pivot from 45 degrees for high moisture material all the way back to 30 degrees for sand and soils with low moisture. Only on a DeSite SLG screener does the operator have the ability to flatten the screen deck with the machines bucket while feeding the screener. The cantilevered suspension gives the operator maximum control over the screening process.

Power Box

Starting at the source you will find our heavy duty 25ft (10 gauge) electrical cord that connects to our watertight power box. Inside the power box you will find a bus bar and starting capacitor that stores the energy necessary to start the vibratory pack rotating. The vibratory pack will spin up the dual eccentric armature to 3600 rpm, supplying a centrifugal force of 560 ft/ lbs. Once up to speed the vibratory pack transfers the vibration through the vibratory motor mounting plate, through the vertical tubes, and then across our crowned and side tensioned screen mesh. Our screen deck design has been engineered to withstand the harmonic vibration that is needed to keep material moving across the screen deck. The 78 ProScreen can be powered up with standard 120 volt land power as long as the distance from the power source is under 75ft and you are using a heavy duty 10 gauge electrical cord.Grab and Go Portability

Portability is another key component to production and productivity when using compact equipment to feed a portable screener. Keeping the screener close to the pile being screened cuts travel time back and forth to the pile resulting in higher production and higher profits.The 78 ProScreen can be moved easily around the work site using your pallet forks or with your machines bucket using our Bucket Transport Lugs. The 78 ProScreen design has lift pockets for quick and easy movement with pallet forks. We also have designed lift lugs that can be inserted into the lift pocket openings for onsite movement using the bucket on your machine. This gives you the ability to move the screener around the worksite with your bucket so you do not have to change to pallet forks.

Versatility

The 78 ProScreen can be fed with many types and sizes of compact equipment from skidsteers, to excavators, bucket tractors, and compact loaders. The screeners can be fed efficiently from the front, back and from either side. The 78 ProScreen can be fed with buckets up to 78 inches wide from the back or front. When wanting to feed the screener from the side with a compact excavator you can use up to a 36 inch wide bucket.Low Maintenance

The 78 ProScreen has only two grease points where the duplexed coil springs pivot allowing the screen deck to go from 45 degrees all the way back to 30 degrees. More time spent screening and less time doing maintenance means lower operating costs with higher production each day. Our 3600 rpm electric vibratory packs are sealed away from the elements of dirt and moisture. A big advantage to our 78 ProScreen design is the ability to power the screener with a small compact 3500 watt generator. With a good quality 100ft 10 gauge power cord, your generator can be away dust and dirt that is so hard on engines.

Transport

The 78 ProScreen has been designed to load length wise or cross ways on the trailer leaving room for your skid steer or compact excavator.

Accessories

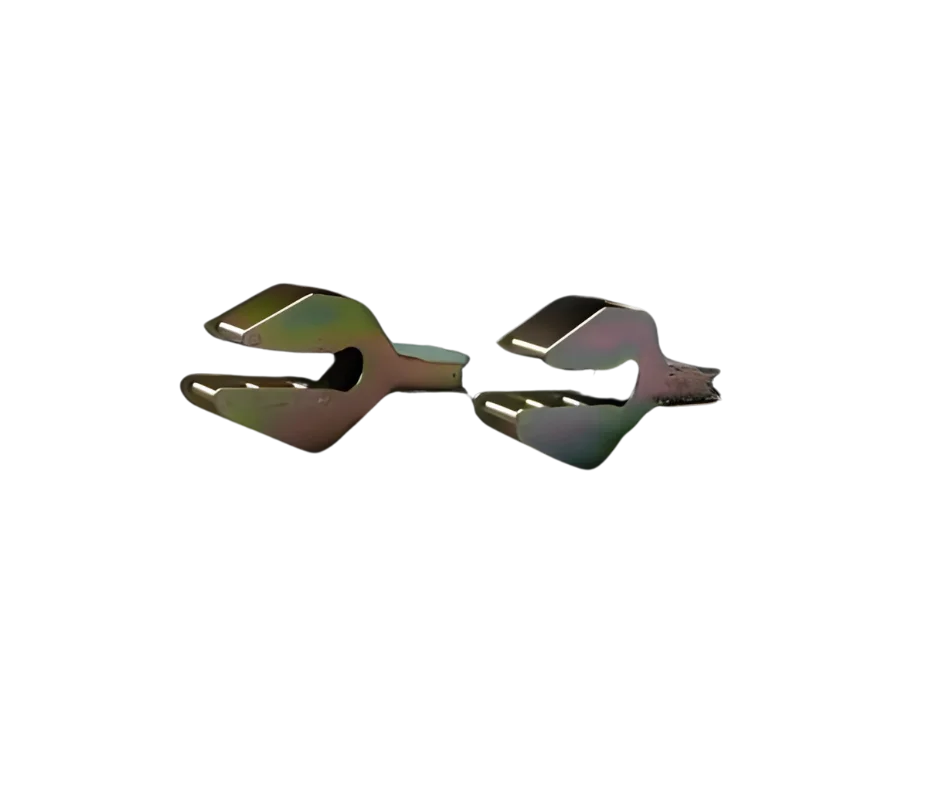

Bucket Transport Lugs

For moving the 78 ProScreen around onsite our Bucket Transport Lugs will saves time and the need for having pallet forks onsite. The lugs slide directly into the fork pockets with a retention hole to lock them in place. Once installed you will have the ability to pick up the screener with your bucket and move the screener quickly. No hitch, no wheels, no wiring, and no digging.

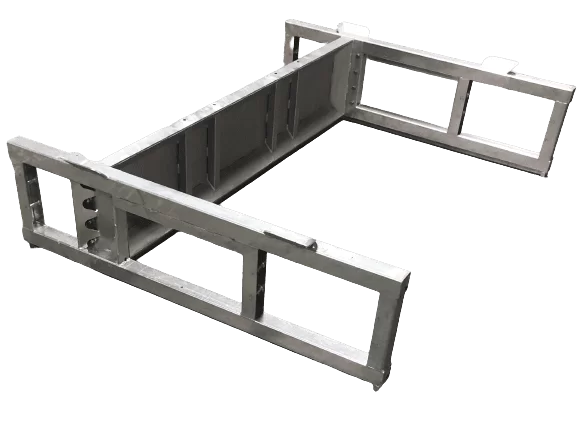

18 Inch Riser Box:

Dimensions: 6ft x 8ft x 18in Weight: 500lbs

Affordability

When you compare design, durability, portability, and maintenance, it is easy to see the 78 ProScreen is without a doubt the most cost effective way to turn waste into saleable product. The simplicity of the design, using the perfect balance of vibratory, slope, and gravity makes the 78 ProScreen the absolutely best value and fit for working with compact equipment.Nothing compares with our low price and design.

Warranty

The 78 ProScreen is such a rock solid tough screener that we now offer a 2 YEAR REPLACEMENT WARRANTY on the structure and workmanship when under normal use. All electrical components come with our 1 YEAR REPLACEMENT WARRANTY.Machine Specifications

Machine Dimensions

- Screen Box Width: 96 inches

- Screen Box Height: 88 inches

- Screen Box Depth: 54 inches

Weight

- Total Weight: 2000 lbs

Screen Deck

- Screen Deck Width: 80 inches

- Screen Deck Length: 52 inches

- Screen Deck Surface area: 29sq/ft

- Screen Deck Tilt Angle 45 to 30 Degrees

- Cantilevered screen deck suspension

Screen Deck Suspension

- Cantilevered Coil Over Leaf Spring

Vibratory System

- Vibratory Style Dual Eccentric Armature

- Eccentric Rotation 3600 rpm

- Amperage Draw 5 Amps per motor (3600rpm)

- Eccentric Force 760 lbs per/revolution

- North America 110 Volt ( 60 Hertz )

- Europe 220 Volt ( 50 Hertz )

- South America 110 Volt ( 60 Hertz )

Productivity

- 15 to 30 yards per hour depending upon mesh size, material, and the size and type of machine feeding the screener.

Screener Line Drawings

78 ProScreen Side View

78 ProScreen Front View

78 ProScreen Side View

78 ProScreen Front View

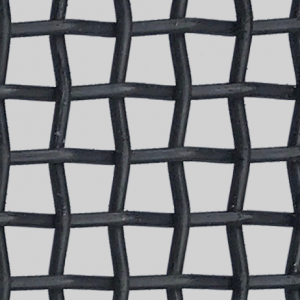

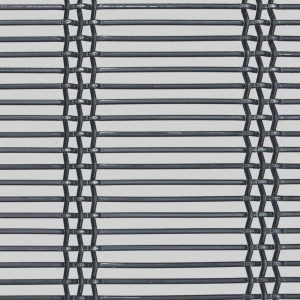

Screen Mesh

The 78 ProScreen can be fitted with multiple mesh sizes staring as small as 1/8 inch all the way up to 4 inches. The ability to fit the 78 ProScreen with multiple mesh sizes allows screening for sand, topsoil, compost, gravel rock and wood waste. Changing the mesh to an alternate size will take under 10 minutes. All of our mesh is constructed from 65mn steel for maximum wear using double lock crimp dies for tight durable fit. We offer all the sizes listed below. Custom screen sizes are available on request. We offer you a wide variety of mesh size for your new DeSite screening machine. From just 1/8 inch to 4 inches with either a square pattern or an elongated mesh. The square pattern produces a more accurate sizing and used is primarily used for gravel and rock, while elongated is designed to handle soils and material with higher moisture. It is important to note that the size of the finished product going through will be smaller than the mesh opening size.Square

| Mesh Size | Pattern | Product Size |

|---|---|---|

| 5/32" x 5/32" | Square | 1/16" |

| 1/4" x 1/4" | Square | 1/8" |

| 3/8" x 3/8" | Square | 1/4" |

| 1/2" x 1/2" | Square | 3/8" |

| 1" x 1" | Square | 3/4" |

| 2" x 2" | Square | 1-1/2" |

| 3" x 3" | Square | 2" |

| 4" x 4" | Square | 3" |

Elongated

| Mesh Size | Pattern | Product Size |

|---|---|---|

| 3/8" x 4" | Elongated | 1/4" to 5/16" |

| 1/2" x 4" | Elongated | 3/8" to 7/16" |

| 3/4" x 4" | Elongated | 1/2" to 9/16" |

| 1" x 4" | Elongated | 3/4" to 7/8" |

SCREEN AND PRODUCE THE FOLLOWING PRODUCTS

- Recycled Asphalt

- Wood Grindings

- Drainage Rock

- Pipe Bedding

- Topsoil Soils

- Bark Mulch

- Rocks

- Dirt

- Sand

- Gravel

- Compost

- Pea Gravel

- Winter Sand

- Septic Stone

- Decorative Rock